DESIGN PHILOSOPHY

Patented assembly methods

Axjo has a number of patented assembly methods. Our most famous are Light, Micro and Nano.

Smooth design

All drums can be supplied with three different sizes of starting hole. All have a smooth design to reduce impact on the cable.

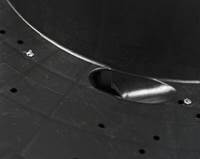

Cut-out for automatic windings machines

Cut-out for automatic winding machines, such as Windak and Müller. It is available on all Axjo reels.

Two-way starting hole

Two-way starting hole. The operator does not need to turn the drum in the machine. The operator can start from both sides.

Built-in drainage holes

Drums over 500 mm have built-in drainage holes. This helps keep your cable dry.

Best delivery drum solution

Axjo has the best delivery drum solution on the market for fiber producers. This is the fiber cut-out on a 700 drum. The fiber versions are available from 700-1190 mm.

Made with a draft

To reduce the risk of a stoppage in the winding equipment, our HD drums are made with a draft in the centre hole. This draft also increases the life span of the drum.